Toolcon Systems

Toolcon Systems was established in 2001 with a vision to serve industries that required high precision machined parts and assemblies.

We have developed a reputation with clients as an outstanding source for advanced machining and assembly service.

We have been honored to qualify and meet the critical needs of many leading companies both in India and overseas, most of whom we continue to serve until now since inception.

We are ISO9001:2015 certified to support a variety of market applications in industries including Aerospace, Energy, Industrial Applications and more.

Our clients are geographically spread across India, Europe, US and Asia.

Our Capabilities

Toolcon Systems is one of the few companies in the country that has both conventional and multi-axis machining capabilities with higher precision accuracy.

We can handle a wide variety of jobs which weigh as low as 20 grams and as heavy as 20 tonnes.

Service

We understand that a quality product delivered late has little value to our Customer.

That’s why we focus on understanding how to service our Customer’s requirements and deliver a quality product the first time, every time.

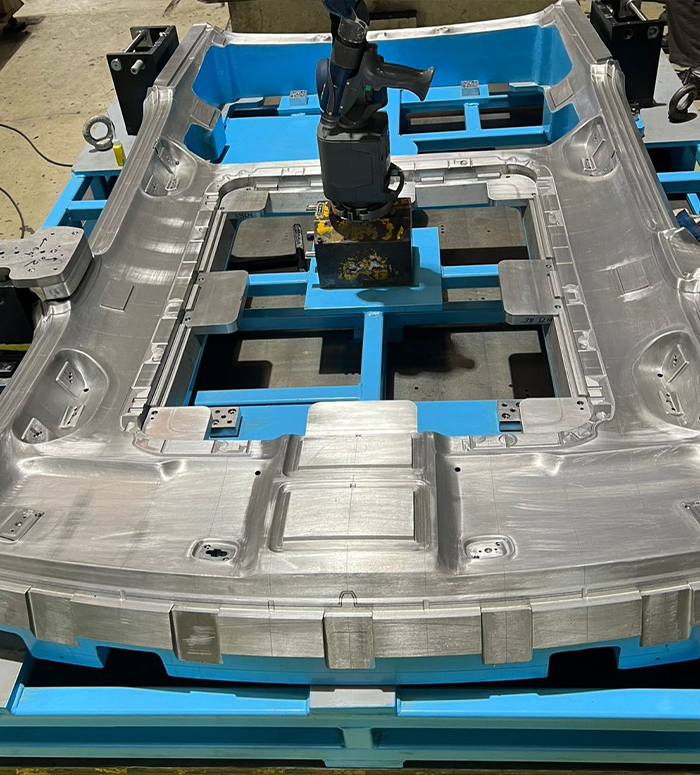

Here at Toolcon Systems, we manufacture precision tooling solutions in jigs, fixtures and dies as per market requirements.

Quality

At Toolcon Systems, quality is everyone’s responsibility.

Our reputation and the success of our business are dependent on the quality of service we provide.

Toolcon Systems quality management system is registered to the ISO 9001: 2015 standards and is certified .

This quality management system ensures that we consistently provide unparalleled quality and unmatched service that meets or exceeds Customer expectations.

Value

Every Customer has a different perspective on value.

That’s why we have made it our business to understand our Customers and focus on meeting their needs beyond quality and service.

It is this approach that ensures our Customers keep coming back, and it’s how we deliver value.

Quality Management

FOD free area

Proper preservation of components

Implementation of risk management, project and configuration management

Implementation of new ME documents for operations

Workshop

Dedicated inventory for each client

Dedicated storage area for raw materials

Proper packaging & dispatch

Our Products

Fixtures

Dies