Over past 25 years Toolcon systems has played a prominent role in Aerospace sector and supplied hi-precision indigenous components, precision fixtures and tools for aerospace programs.

Toolcon systems has been involved in Aerospace C295, Boeing 737,Pilatus PC-12 And many more and provided various hi-precision components and subassemblies for Numerous aerospace Projects.

In the process of its journey Toolcon systems has gained expertise in manufacturing machined components, sub-Assemblies for Fixtures and Dies. Toolcon systems has been supplying Hi-Precision Machined ,fabricated systems to most of the Aerospace, automobiles (Heavy Duty and light duty),Marines, Food industries, Oil and gas, energy, Construction industries.

As the need of the hour in the Aerospace manufacturing, Toolcon systems is working together with Indian and International Aerospace organizations with a strong foot hold in realization of the high precision mechanical solutions Integration meeting all the quality norms of the industry.

Given its historical performance, capabilities and management vision, Toolcon systems is very well placed to meet offset requirements of multi-national companies, which would supply to the Indian Aerospace programs.

Toolcon systems is augmenting its infrastructure facilities continuously with the latest state-of-art equipment to meet all the norms of the industry and to cater the needs of the Indian and international Industry making it a world class manufacturing hub for Defence and Aerospace and many more sectors to cater to all their requirements

Types of fixtures for aerospace and avation sector-

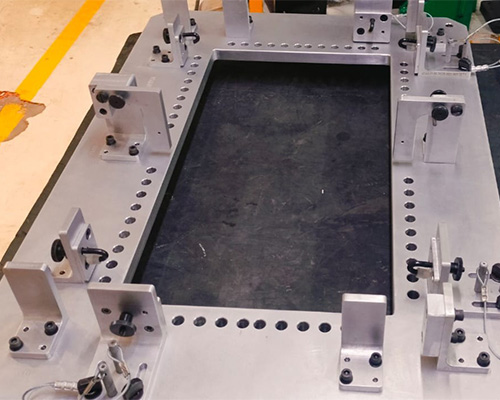

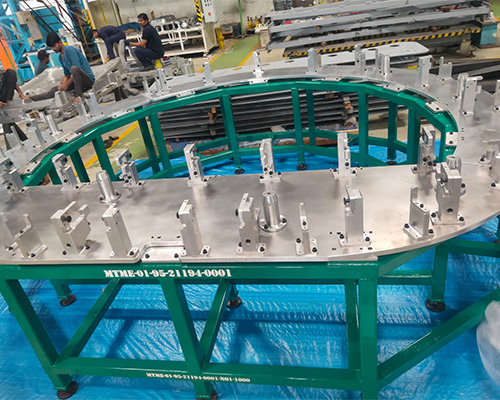

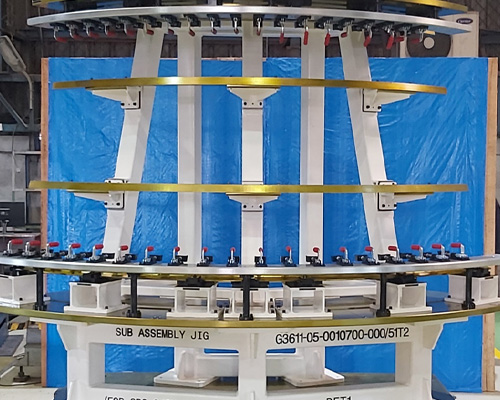

1. Assembly Fixtures-Used to hold and align large aircraft components (like fuselage sections, wings, or stabilizers) during assembly.

- Fuselage assembly fixtures: Align and support fuselage sections.

- Wing assembly jigs: Hold wing spars and skins in proper orientation.

- Empennage fixtures: Used for tail assemblies.

- Final assembly jigs: Integrate major subassemblies into the aircraft.

2. Machining Fixtures :Support parts during CNC machining or drilling, ensuring rigidity and accuracy.

3. Drilling and Riveting Fixtures-Ensure precise hole alignment and fastener placement during skin assembly.

- Drill jigs: Guide tools for consistent hole spacing and depth.

- Rivet fixtures: Support structures during manual or automated riveting.

- Portable drill templates: Lightweight templates for in-situ work on aircraft skins.

4. Inspection Fixtures - Hold parts in a stable position for quality control and dimensional verification.

- Coordinate measuring machine (CMM) fixtures: Used to support parts on CMM tables.

- Go/no-go gauges and checking fixtures: Ensure critical dimensions are within tolerance.

5. Layup Fixtures - Used in the manufacture of composite structures to shape and cure parts.

- Layup tools: Define the shape of composite skins or structures.

- Trim fixtures: Guide trimming or drilling after cure.

6. Trimming Dies - Precisely cut the edge of formed parts (e.g., trimming fuselage skin edges)

7. Inspection and Checking Dies - Used to verify dimensions or tolerances of parts.

- Go/No-Go Dies: Simple check tools for dimensional tolerances.

- Profile Checking Dies: Ensure formed or machined parts match the design profile.